PREV ARTICLE

NEXT ARTICLE

FULL ISSUE

PREV FULL ISSUE

U.S. MINT PATENTS METAL ALLOY FOR COIN PRODUCTION

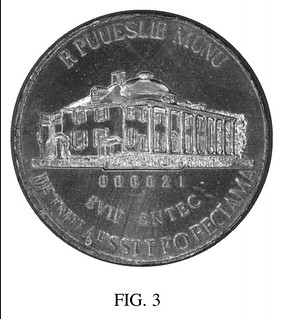

Images from U.S. Patent No. 10,472,703 My Nummis Nova friend Steve Bishop located a U.S. Mint patent I'd recently heard about. Thanks. Here's an excerpt. It includes images of "Martha" test designs. -Editor The metal alloy is a possible replacement for/alternative to cupronickel cladding material used on currently-circulating clad coins. In the preferred embodiment, the (steel) metal alloy cladding material comprises 73-77% iron, 22-26% nickel, 0.2-0.5% carbon, and 1-5% manganese. The cladding material has an International Annealed Copper Standard (IACS) conductivity of less than 2%, a permeability of approximately 1.0-1.1, and a hardness value of 50-70 HRC 15 T (Rockwell Hardness). In alternative embodiments, the steel alloy comprises a monolithic coin or a core that may be plated with other metals. FIELD OF THE INVENTION

BACKGROUND OF THE INVENTION

However, some steel alloys are non-ferromagnetic and have significantly different properties than common steel. To use most steels, stamping tonnage must be increased by more than 20% (relative to copper or cupronickel) to achieve a clean stamping relief result. To be usable, a steel coin must have low strain hardening properties (i.e. be sufficiently soft) for effective stamping, and have a relative permeability that is close to 1.0. A relatively high nickel-steel coin can meet these criteria. If steel containing 18% nickel and 0.60% carbon is quenched in water, the material will be perceptibly softened. If the amount of nickel is raised to 25%, this softening is even more apparent. Generally, as the amount of nickel increases, the steel softens, and a 25% nickel steel can be worked cold almost as easily as German silver or cupronickel. The need exists for a replacement alloy material that is less expensive and more durable (among other things) than the cupronickel coin cladding material that is currently in use. As described herein, the inventors determined that, by manipulating various steel alloys, a nickel steel alloy could be identified and developed for use as an alternative coin cladding material for coins such as US dimes, quarters, half dollars, and dollar coins. The material described herein meets that criteria and is compatible with coin validator/acceptor machines currently in use. SUMMARY OF THE INVENTION

Steve adds: "The patent says that the alloy could also be used as a monolithic blank that could be plated." There have been many attempts over the years to create new materials for coins, but only a small portion succeed and end up in production. Time will tell what happens with this alloy, if anything. -Editor For the complete U.S. Mint patent, see:

Wayne Homren, Editor The Numismatic Bibliomania Society is a non-profit organization promoting numismatic literature. See our web site at coinbooks.org. To submit items for publication in The E-Sylum, write to the Editor at this address: whomren@gmail.com To subscribe go to: https://my.binhost.com/lists/listinfo/esylum All Rights Reserved. NBS Home Page Contact the NBS webmaster

|